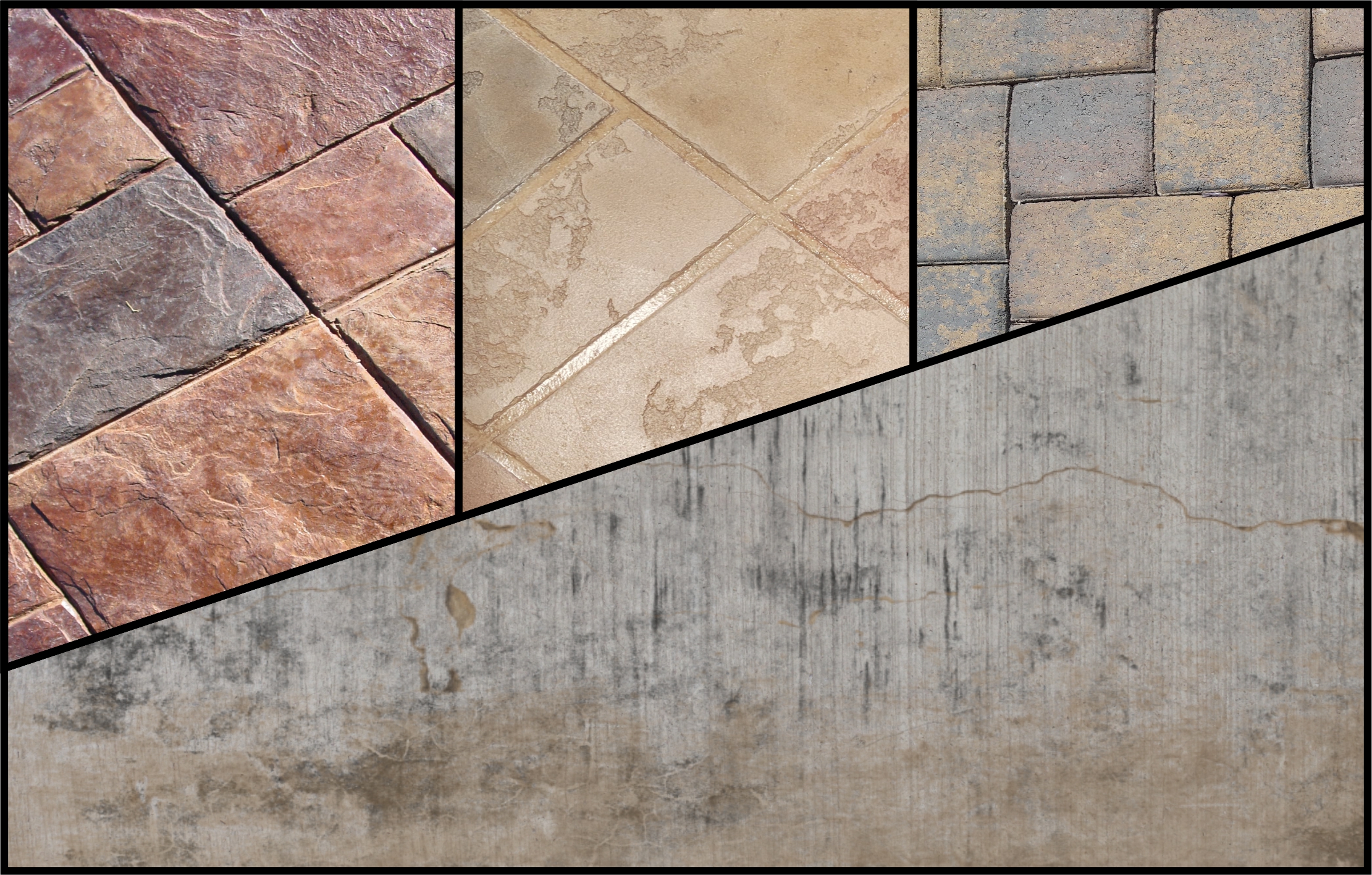

Stamped concrete, a versatile and aesthetic solution for pavements and floorings, has become increasingly popular in contemporary architecture and landscaping. This article explores the origins, development, and diversification of stamped concrete throughout its history.

Origins and Early Development

Stamped concrete traces its roots back to the ancient Roman times when builders used to stamp bricks and stones to create unique pavement patterns. However, the modern form of stamped concrete originated in the 1950s on the West Coast of the United States. It was developed as an economical alternative to traditional materials like natural stone, slate, and brick.

The technique initially involved pressing wooden molds into fresh concrete to imprint textures that mimicked stone pavements. By the 1970s, the technology had advanced with the introduction of polyurethane stamps, which were more durable and offered more intricate designs. This era saw a significant expansion in the variety and complexity of patterns available, including cobblestones, slate, wood, and even seashells.

Technological Innovations and Expansion

Throughout the 1980s and 1990s, the industry witnessed technological advancements that made stamped concrete not only more versatile but also more attractive. Color hardeners and release agents were introduced, enhancing both the durability of the surface and the vividness of the colors. This period also saw the development of better mixing techniques, which allowed for longer working times and more detailed pattern work.

These innovations made stamped concrete a popular choice for public and private projects, from driveways and sidewalks to patios and pool decks. Its ability to mimic high-end materials at a fraction of the cost contributed to its spread globally.

Global Adoption and Modern Uses

By the early 2000s, stamped concrete had become a global phenomenon, utilized in diverse climates and regions. It became particularly popular in regions where cost, durability, and maintenance were key concerns. The flexibility in design also made it a preferred choice for thematic parks, corporate environments, and residential complexes, where custom designs could be created to fit the specific aesthetics of a project.

Modern stamped concrete incorporates not only varied patterns and colors but also different textures and finishes. The introduction of 3D stamped concrete, where the imprint creates an illusion of three-dimensional depth, marked another milestone in the evolution of stamped concrete technology.

Innovation at Sharp Contracting

Enter Sharp Contracting, a trailblazer in the industry since 1989. With a commitment to excellence, Sharp Contracting has developed revolutionary techniques that address the shortcomings of stamped concrete. Their methods ensure the most consistent color and texture, providing clients with quality and reliability assurance.

Sharp Contracting’s Approach:

In contrast, Sharp Contracting has revolutionized stamped concrete craftsmanship with its innovative approach. By leveraging cutting-edge techniques and advanced materials, Sharp Contracting has overcome many of the limitations associated with conventional methods.

Thin, flexible mats molded from genuine stone allow for precise texture transfer, enhancing stamped surfaces’ authenticity and visual appeal. Liquid release agents are uniformly applied, ensuring flawless texture transfer onto the concrete surface without the mess associated with powder release agents.

Controlled pouring enables precise placement of concrete, reducing wastage and maximizing accuracy. Simultaneous concrete surface finishing during pouring streamlines the process, optimizing efficiency and ensuring consistent quality. Stamping is executed at the optimal curing stage throughout the entire pour, resulting in uniform texture and appearance.

Sharp Contracting’s stamped concrete methodology represents a significant advancement in the industry, offering superior quality, efficiency, and consistency compared to conventional methods. By challenging the status quo and embracing innovation, Sharp Contracting has set a new benchmark for excellence in stamped concrete craftsmanship.

Challenges and Sustainability

Despite its many benefits, stamped concrete does face challenges such as cracking over time and the need for resealing to maintain its appearance. These issues have spurred further innovations in composite materials and sealing technologies.

Moreover, the increasing emphasis on sustainable construction practices has led to the development of eco-friendly alternatives within the stamped concrete industry, such as the use of recycled materials and low-VOC (volatile organic compounds) sealants.

Conclusion

Stamped concrete has come a long way from its humble beginnings to becoming a staple in construction and design landscapes worldwide. It remains a favored choice due to its cost-effectiveness, versatility, and durability, continually evolving with technological and material advancements. As it adapts to new environmental standards and design trends, stamped concrete is poised to remain a key player in the paving industry for years to come.