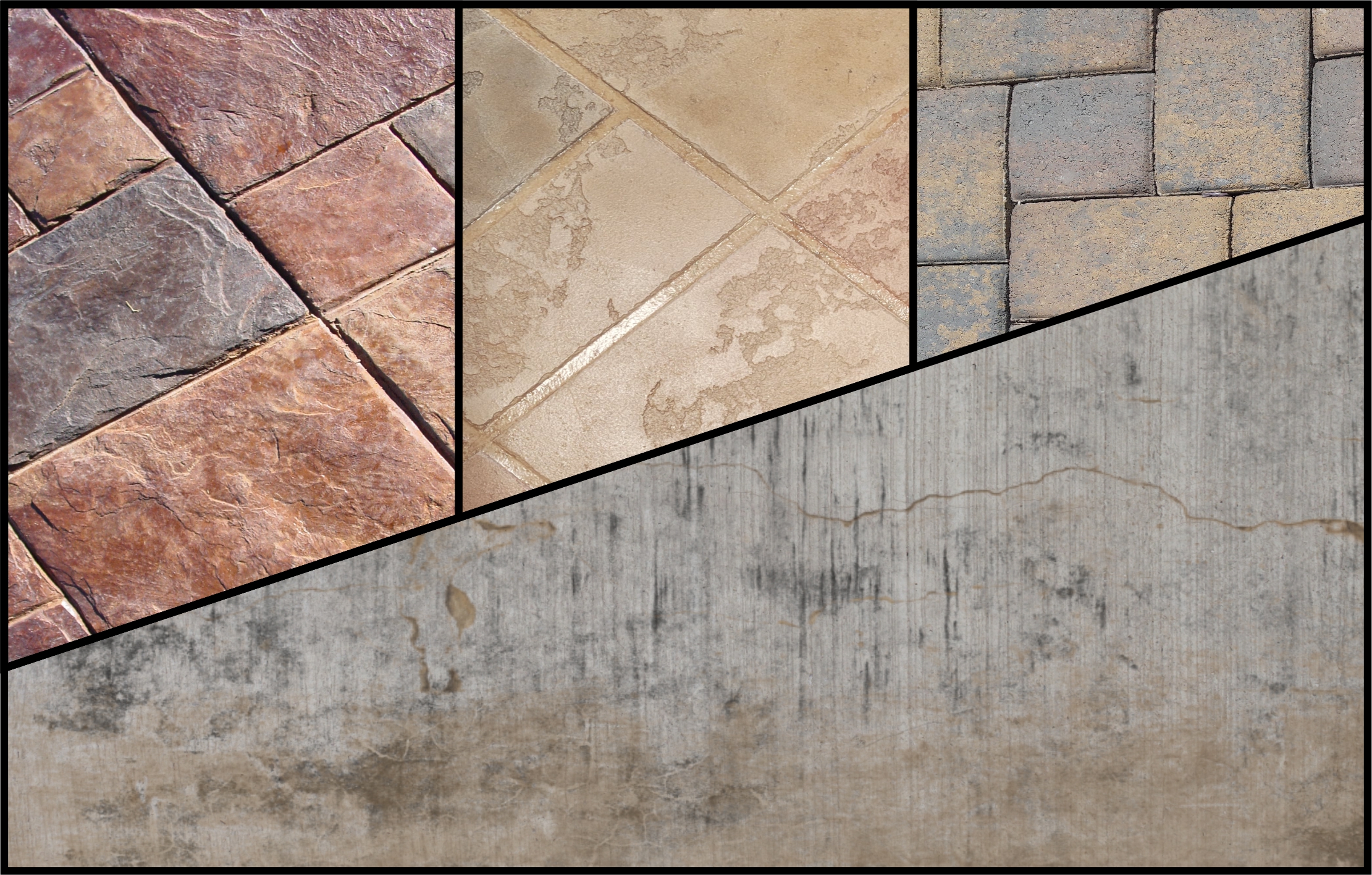

Stamped concrete has long been a staple in architectural design, offering the aesthetic appeal of natural materials coupled with the durability of concrete. However, not all stamped concrete is created equal, and the methods employed can greatly impact the quality and longevity of the final product. In recent years, Sharp Contracting has emerged as a frontrunner in the industry, challenging conventional approaches and ushering in a new era of stamped concrete craftsmanship. Let’s explore how Sharp Contracting’s methods stack up against the conventional practices still prevalent among other companies.

Conventional Methods:

For many years, the majority of stamped concrete companies have relied on traditional processes developed decades ago. While these methods have served their purpose, they come with their fair share of limitations.

One of the primary drawbacks of conventional methods lies in the lack of control over the mix and pour. Concrete is typically poured all at once from a truck, resulting in rushed processes and limited precision. Additionally, the use of thick, rigid mats molded from real stone can lead to challenges in achieving full texture transfer, impacting the authenticity of the finished product.

Moreover, the application of dry powder release agents, while effective for texture transfer, can sometimes be messy and inconsistent. Stamping timing also poses challenges, as it must occur throughout the entire pour, often resulting in variations in texture and appearance. Lastly, the need for return visits to wash excess release and seal concrete can lead to delays in project completion.

Sharp Contracting’s Approach:

In contrast, Sharp Contracting has revolutionized stamped concrete craftsmanship with its innovative approach. By leveraging cutting-edge techniques and advanced materials, Sharp Contracting has overcome many of the limitations associated with conventional methods.

Thin, flexible mats molded from genuine stone allow for precise texture transfer, enhancing stamped surfaces’ authenticity and visual appeal. Liquid release agents are uniformly applied, ensuring flawless texture transfer onto the concrete surface without the mess associated with powder release agents.

Controlled pouring enables precise placement of concrete, reducing wastage and maximizing accuracy. Simultaneous concrete surface finishing during pouring streamlines the process, optimizing efficiency and ensuring consistent quality. Stamping is executed at the optimal curing stage throughout the entire pour, resulting in uniform texture and appearance.

Conclusion: In conclusion, Sharp Contracting’s stamped concrete methodology represents a significant advancement in the industry, offering superior quality, efficiency, and consistency compared to conventional methods. By challenging the status quo and embracing innovation, Sharp Contracting has set a new benchmark for excellence in stamped concrete craftsmanship. For projects that demand the highest standards of quality and aesthetics, Sharp Contracting stands as the premier choice, reshaping the landscape of architectural design with its commitment to excellence and innovation.